MAXIMUM PRESSURE STABILITY FOR YOUR GAS SUPPLY WITH DOME PRESSURE REGULATORS

If highest pressure stability even at inlet pressure or withdrawal fluctuations is required, dome-loaded pressure regulators are the best choice. There is a wide field of different applications. WITT dome-loaded pressure regulators are proven in many applications all over the world.

Application examples of dome loaded pressure regulators:

Dome-loaded pressure regulators at cryogenic tank vapourisers

- A back-up supply to a 24/7 gas generator – the back-up will cut in at precisely the right pressure and will be seamless to the downstream process. This means 100 % availability. Can also be used for peak-shaving.

- Purge gases at high flow rates – at just under the downstream relief valve

set-pressure - Laser-assist gases – accurately delivered without always needing a 37 barg (536 psi) MAWP tank-rating

Gas supplies, such as tube-trailers, cylinders bundels and buffer tanks

- Accurate control and high flow rates, even when the inlet pressure falls to within 1 bar (14.5 psi) above the outlet pressure – meaning more useable gas can be taken, thereby reducing replenishment/logistics costs

- Accurate outlet pressure control from PSAs and VSAs – smoothing out any pressure variations and improving the downstream process performance and safety

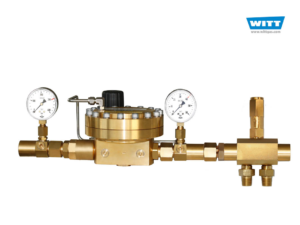

Dome pressure regulators in CO2 systems for welding gases

The project is supplying welding gas mixtures to Indian Railways at Raebareli. CO2 (from cylinders) and Argon (from a cryogenic tank) are supplied into WITT Gas Mixers. The customer needs stable flow even in fluctuating demands from the mixers depending on the usage rates. The dome pressure regulator 737LE-HD/S.is designed to deliver stable outlet pressure irrespective of flow fluctuations, and irrespective of changes in upstream pressures. With the WITT doem-loaded pressure regulator, the customer has had trouble-free operation for almost a year, no production loss or downtime, with no stoppage of operation due to CO2 supply failure, and no variation of utlet pressure with flow.

The project is supplying welding gas mixtures to Indian Railways at Raebareli. CO2 (from cylinders) and Argon (from a cryogenic tank) are supplied into WITT Gas Mixers. The customer needs stable flow even in fluctuating demands from the mixers depending on the usage rates. The dome pressure regulator 737LE-HD/S.is designed to deliver stable outlet pressure irrespective of flow fluctuations, and irrespective of changes in upstream pressures. With the WITT doem-loaded pressure regulator, the customer has had trouble-free operation for almost a year, no production loss or downtime, with no stoppage of operation due to CO2 supply failure, and no variation of utlet pressure with flow.

Dome-loaded pressure regulators with electrical proportional valve

The 3 lines for oxygen and propane each go via a dome. The pilot control gas is regulated via proportional valves controlled by a PLC. Automatic adjustments of the Pilot Gas pressure regulate the flowrates into the burners, thereby controlling the cutting process. The domes minimise any variations, and allow for optimal cutting, at a fraction of the price of a fully electronic control system.

WITT dome-loaded pressure regulator 757LE/S with proportional valve

Dome-loaded pressure regulation sets operated by an electrical proportional valve instead of a pilot pressure regulator are used for processes that require different working pressures. For example with this solution a burner control can be optimised by setting different gas pressures depending on the respective material. By a stored program control (SPC) with amperage or voltage the pressure regulator can be fast and easily controlled. A manual setting of the working pressure is not required. The wide pressure range from 0.5 to 30 bar makes such a system outstanding.

Nitrogen supply switch-over unit

T he customer demanded a very high performance and reliable pressure control of a nitrogen supply for the packaging of potato snacks. To meet this challenge, WITT installed two supply lines in parallel, each with a dome pressure regulator set 767LE/S.

he customer demanded a very high performance and reliable pressure control of a nitrogen supply for the packaging of potato snacks. To meet this challenge, WITT installed two supply lines in parallel, each with a dome pressure regulator set 767LE/S.

The gas is regulated from 12 bar down to 6 bar. The dome pressure regulators function independently. To allow for maintenance, ball valves enable each Dome to be isolated. This parallel arrangement gives 100 % up-time.

Redundancy-capable pressure control for Vacuum Annealing

The process required a constant 10 bar supply of nitrogen into the annealing furnace, from a 13 bar tank. The customer requested a parallel redundant system, plus a roof cover.

The process required a constant 10 bar supply of nitrogen into the annealing furnace, from a 13 bar tank. The customer requested a parallel redundant system, plus a roof cover.

The average gas flow per furnace should be around 150 Nm3 / h, and 4 should be mounted, allowing up to 600 Nm3 / h. To allow for major process upsets requiring emergency N2 blanketing, a maximum flow rate of 1 600 Nm3 / h was set. Because the WITT Dome sets are also able to regulate small flows precisely, a single redundancy capability was designed for using the WITT 757 Set.

Dome-loaded pressure regulators in central gas supply systems

In many applications dome-loaded pressure regulator sets, e.g. 757 LE/S or 747 LE/S operated by a pilot pressure regulator, are used behind the gasifier of a central gas supply system. High gas flows are regulated to a stable working pressure independent of high withdrawal fluctuations. A re-adjustment of the gas pressure is not necessary due to some design-engineering details of WITT dome-loaded pressures regulators such as the own medium control or the closed dynamic system. As completely mounted pressure regulation set, including the DN50 flange connection, pilot pressure regulator or proportional valve, gauges, etc., the regulators can be used and integrated without any additional effort. The wide temperature range down to -30° Celsius allows an outdoor installation even in the winter.

Another dome-loaded pressure regulator application is the supply of gas mixers. WITT dome-loaded pressure regulators ensure stable gas pressure for the mixer. Even when having withdrawal fluctuations the gas mixing ratio stays always stable.

Oxygen inerting of flame lances

The customer required an electronic pressure control system, with redundancy, to deliver a minimum flow of 2 200Nm³/h at up to 14 barg, from an inlet pressure of 15 barg. This was achieved with one WITT dome pressure regulator set 767LE / S (with proportional control) per line.

Upon request, a motorised shut-off valve was included on the inlet, to allow complete shut-off. Additionally, manual shut-offs before and after each regulator were included, to allow the evacuation of each line. The design, build and commissioning of the system was undertaken by WITT partner Gustus & Partner GmbH, in cooperation with the customer.

Individual pressure regulation solutions are available in many different versions and layouts. For example safety relief or solenoid valves can be integrated to protect the process. By using solenoid valves, controlled by pressure transmitters, the gas supply can be cut off in the case of a pressure increase.

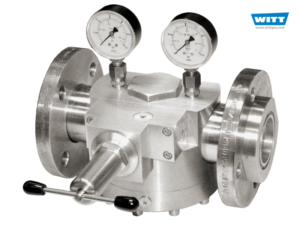

Dome-loaded pressure regulators in 1.4404 stainless steel (316L)

For applications and processes where non-ferrous metal is not suitable or favored, WITT offers a wide range of stainless steal dome-loaded pressure regulators. For our products we use high quality 1.4404 stainless steal (316L). This material offers a high resistance against corrosion.

Dome-loaded pressure regulator as manifold pressure regulator

The dome-loaded pressure regulator 737 LE-HD/S in combination with the WITT safety block is a perfect solution solution as manifold pressure regulator. The high inlet pressure of max. 300 bar and the the flow rate of up to 2000 Nm³/h allow the reliable gas supply of all processes. The safety block with indidually configurated safety relief valve and burst disks allows a high relief capacity. By this the downstream process is protected against possible failures.

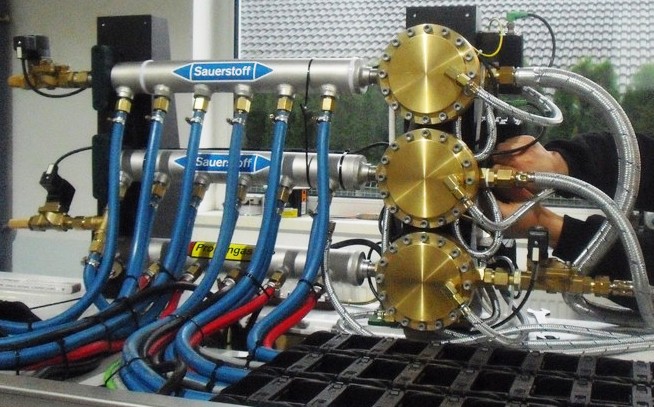

Customized Dome System for oxygen

This customised system, fully assembled in a lockable cabinet, controls the supply of oxygen into an industrial waste water treatment plant.

This customised system, fully assembled in a lockable cabinet, controls the supply of oxygen into an industrial waste water treatment plant.

The detailed specification to ensure a flow rate of some 1 000 m³ / h, was drawn up by specialist WITT company Gustus & Partner GmbH in conjunction with the customer, pre-commissioning TÜV certification.

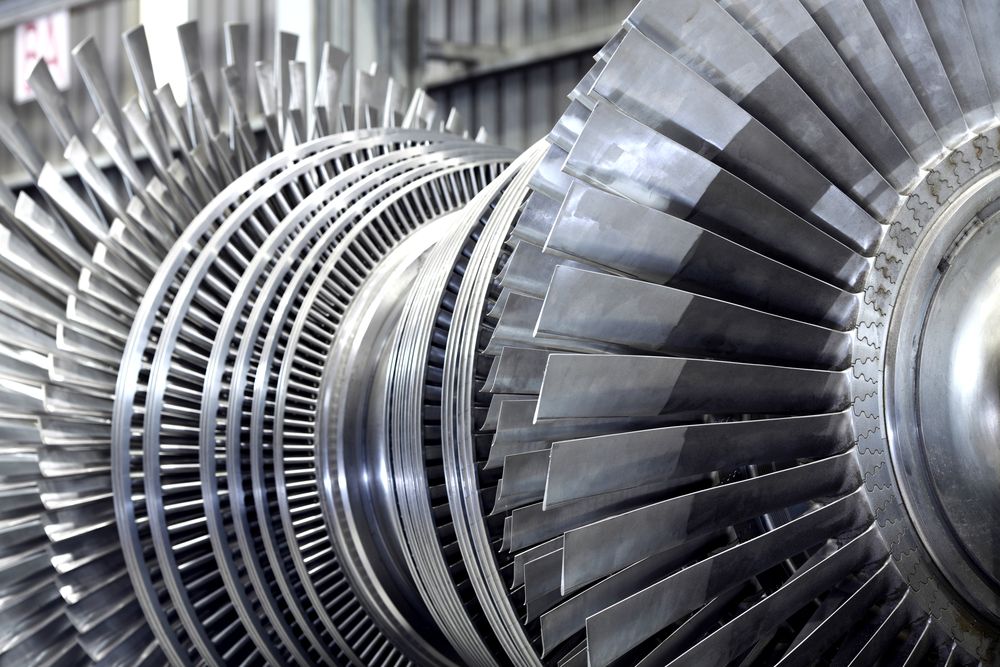

Pressure regulators built into compressores and turbines

- Accurate outlet pressure control – smoothing out any pressure variations

and improving the downstream process performance - Seal-gases control – reducing friction, energy use and maintenance

requirements

Dome pressure regulators for pipeline gas consumption metering

- Accurate pressure control meaning increased metering accuracy

- High flow with minimal ΔP

Downloads

Data sheets dome-loaded pressure regulators PDF

Brochure dome-loaded pressure regulators PDF

Quotation request

Do you have questions regarding dome-loaded pressure regulators or do you require a quotation? Talk to us about your requirements or use our request form.